Timber Veneers.

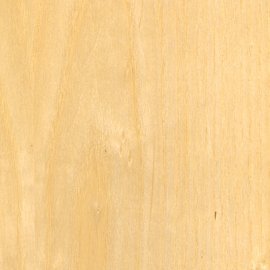

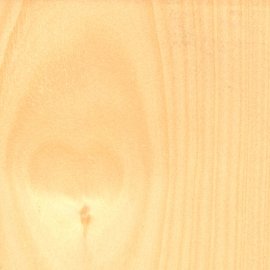

Natural timber veneers are the ideal solution to add natural and organic warmth to any space.

Real Timber Veneer

At Timberwood Panels, Timber Veneers are our specialty.

We have first class, best available colour, grain, texture uniformity throughout our comprehensive range of species. We source species both locally and internationally to ensure we have the unique natural beauty of real timber.

Whatever the choice for your project, Commercial or Domestic, from Stylish Corporate Boardrooms, unique furniture, or warm and inviting Partitions, Timberwood Panels Timber Veneers provide the inspiration to create the perfect solution to your interior and is only limited by your imagination.

Being a natural product it’s important to note that the same timber species can vary greatly in colour and pattern, therefore we invite you to contact us for a batch control sample.

-

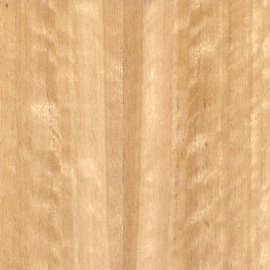

Timberwood Panels are giving Timber Veneerboard a new look. Ideal for feature doors and panels in commercial and domestic bathrooms, kitchens, furniture and joinery, our Timber Veneer Wire Brush Service can be applied to most of our Timber Veneers.

Using a revolutionary sander allows Timberwood Panels to apply a wire brush finish giving a more defined grain to the board. This process favours crown cut veneers but the final look will vary from species to species creating an original and unique look for your feature.

The Minimum size for this service is 0305x0120x3.6mm with Maximum size being 3660x1250x50mm.

-

All pressing substrates must be flat and have a solid core. Raw materials such as medium density fibreboard (MDF) or particleboard are ideal for pressing as they have been engineered to withstand the pressure and heat of a hot press along.

-

HOT PRESSING MINIMUM MAXIMUM

Press Length 1200mm 3650mm

Press Width 750mm 1540mm

Press Thickness 1mm 60mm

Pressing veneer onto foreign substrates is possible, however the following guidelines need to be followed:

Substrate cannot be pre-finished or have any kind of coating on the pressing surface.

All substrates should be supplied oversized, various elements of the pressing cycle can impact the overall size of the board/substrate; infeed, outfeed, handling, etc

Substrates must be free of any machining; holes, rebates, grooves, etc. Any voids in the substrate can compromise the bond between veneer and substrate

Substrates must be free of any metal objects i.e. hardware, screws, nails, etc

To prevent bowing and equal thicknesses, veneer should be pressed on the opposite side (back) of the face

As an example, please see below guidelines for pressing onto a door:

Ensure the door is solid core, without any internal voids

Do not drill/rebate any hardware, holes and voids in the surface as this will compromise the veneer bond

Consider the press limitations when choosing a door size

To prevent damage please supply the door oversized as the door can be re-cut, once veneer has been applied

Mark the door clearly as to which faces are to have veneer

-

BOARD TRIMMING MINIMUM MAXIMUM

Trim Length 1800mm 3650mm

Trim Width 750mm 1350mm

Trim Thickness 3mm 60mm (weight dependant)

-

BOARD SANDING MINIMUM MAXIMUM

Sanding Length 1800mm 3650mm

Sanding Width 750mm 1350mm

Sanding Thickness 3.6mm 60mm (weight dependant)

Important Notes:

Crossbands can be trimmed and sanded

Sheets cannot be sanded without being trimmed

Sanders cannot calibrate boards/sheets

Sanding of custom veneer presses (doors) is subject to inspection

Sheets over 1350mm in width can be pressed but will be supplied untrimmed and unsanded, due to above limitations.Item description

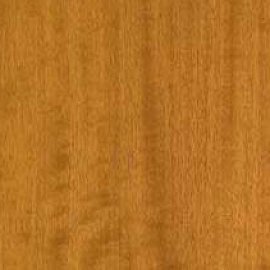

American Cherry

American White Oak

American Walnut

Anegre

Baltic Pine

Beech

Blackbean

Blackbutt

Blackheart Sassafras

Backhole Blackbutt

Blackwood

Brushbox

Bubinga

Clear Radiata Pine

European Ash

European Birch

Golden Sassafras

Hoop Pine

Ironbark

Ironbark Red

Jarrah

Knotty Pine

Myrtle

New Guinea Rosewood

Oregon

Plantation Oak

Queensland Cedar

Queensland Cherry

Queensland Maple

Red Gum

Rock Maple

Sapele

Sycamore

Sydney Blue Gum

Tasmanian Ash

Tasmanian Myrtle

Tasmanian Oak

Teak

Victorian Ash

Wenge

Western Red Cedar

Wormy Chestnut